- Machine Will Be Suitable for 5 ML TO 50 ML VIAL

- Machine Will Be Suitable for 20 mm Rubber Stopper

- Machine Will Be Suitable to Fill 50 mg to 1250 mg (Single Dose) with the help of ¼ & 3/8 size powder wheel and Depends on Characteristic of Powder.

Input Specifications:

| Input Specifications: Container Size* | Round Shape : 22 mm to 55 mm

Respective Height : 25 mm to 110 mm |

| *can be supplied as per customer’s requirement | |

Basic Machine Change Parts :

Basic Machine Will Be supplied with 10 ML change parts.

Interlock & Special Features :

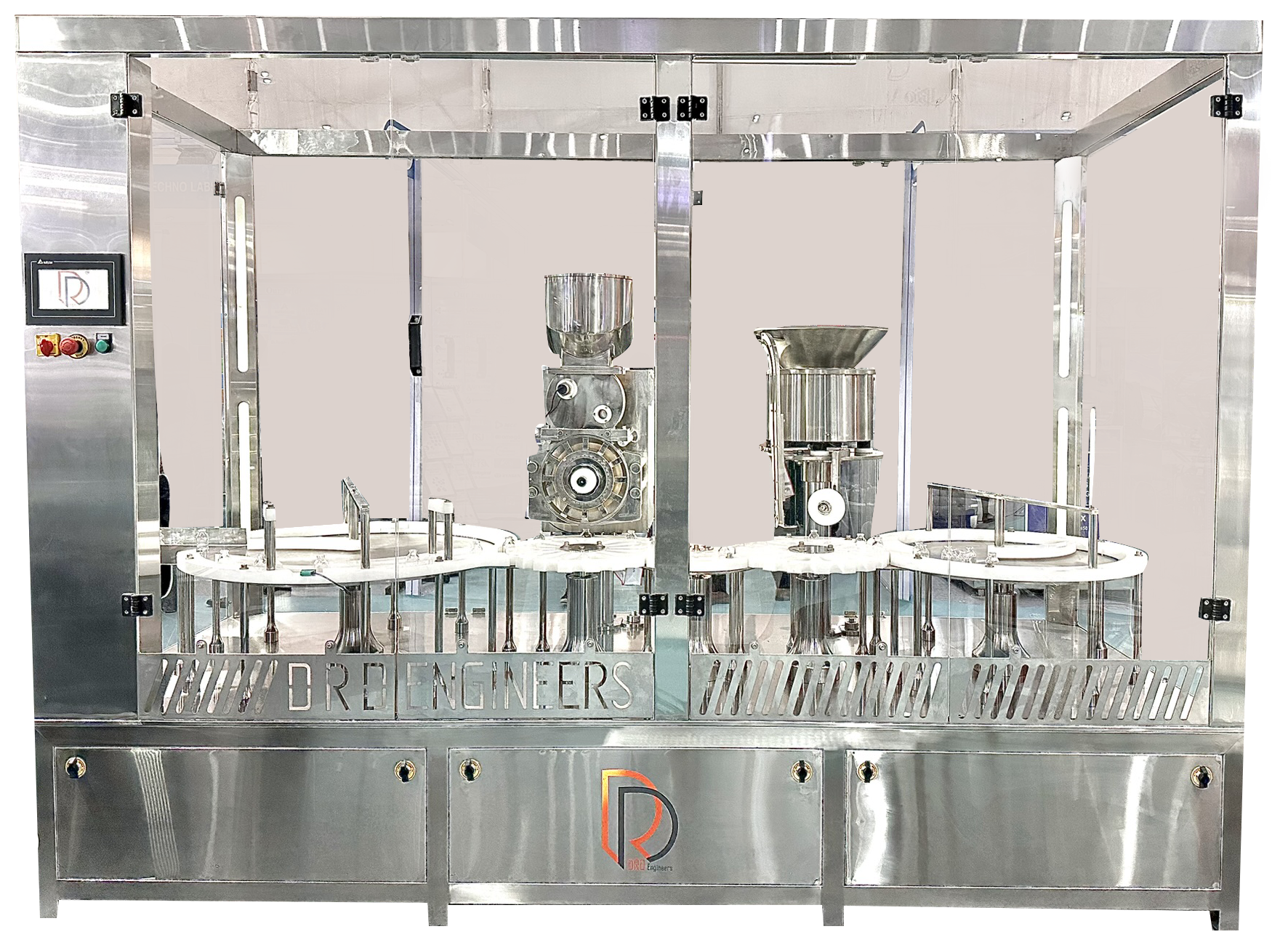

- cGMP Model.

- Output Speed – 110 Vials/Minute (For 10 ML Vial).

- Easy access to all sterilisable parts.

- Fallen Vial in In-feed Turn Table- Machine Stop Sensor.

- No Vial at In-feed Machine Stop Sensor.

- No Vial- No Fill.

- No Rubber Stopper in Suite- Machine Stop Sensor

- Low Air- Machine Stop Sensor.

- Low vacuum Machine Stop System.

- Vial Counter at Out-feed.

- Maximum Accumulation at Out-feed machine Stop Sensor.

- Individual Servo Motors for Star Wheel and Powder Wheel.

- No powder in primary hopper, machine stop sensor.

- Powder Check Window in Primary Hopper.

- Specialized Piston to avoid dusting during filling operation.

- Multiple Dosing System.

- Cushing type pneumatic Cylinder to reduce Noise Level.

- Rubber Stopper Star Wheel work in Gear Motor.

- This is a silent performing machine.

- Suitable for various type of container.

- Reduction gear ensures jerk free and noiseless operation.

- Minimum Change over Time of change parts.

Scope of Supply:

- Machine Frame & Body Structure SS304

- In-feed Turn Table

- Conveyor Belt

- Out – feed Turn Table

- Pre and Post Nitrogen Gassing

- Powder Filling Head with 3/8 size wheel

- Rotary Type Pick & Place Rubber Stoppering Unit

- MOC of All Contact Parts- SS316 and 304

- Automation

- Basic Machine with Change Parts

- Toughen Glass Cabinet

Optional Features (With Extra Cost) :

- Sampling system (As per your requirement, you can set your samples. If you set 5000 Vials the samples will be automatically come out at outside track.).

- Swing Conveyor for easy movement to operator from front side of machine to backside.

- Dry Vacuum pump for powder shucking.

- Peristaltic Pump for Media Filling

- (Benefits of Peristaltic Pump)

- If you use peristaltic pump, then sterilised parts will be less. Minimum time will be required for volume settings. In future, greasing type of liquid will come then there will be issue of dropping.

- Linear Vibrator (For free loading system)

- (Vibrator bowl which is fitted in the Machine, the capacity of Rubber Plug is 1000 to 1200 Nos. approximately, so you have to open the door and load the Rubber Plug in every 10 Minutes. So Linear vibrator bowl capacity is 5000 to 5500. If you follow optional features (Linear Vibrator Bowl) you have to load Rubber Plug in 1Hr therefore you do not have to open the door.

- Canister Loading System Butterfly Vial.

| Technical Specifications: Model No. | CPMPF– L – FILL – 2 – S110 |

| Direction | Left to Right |

| Production Rate | Up to 110 Vial/Min. |

| Electrical Supply | 5.5 HP |

| Power Requirement | 5 Core Wired System Three Phase 415 Volts |

| Working Height | Adjustable From 900 To 950 MM |

| Accuracy for Weight Variation Limit | +/- 2% |

| No. of Powder Head with Servo | 1 Nos. |

| No. Rubber Stoppering Unit | 1 Nos. |

| Machine Size | 3300mm (L), 1100mm (W), 1800mm (H) |

| Machine Weight | 800 to 1000kg |