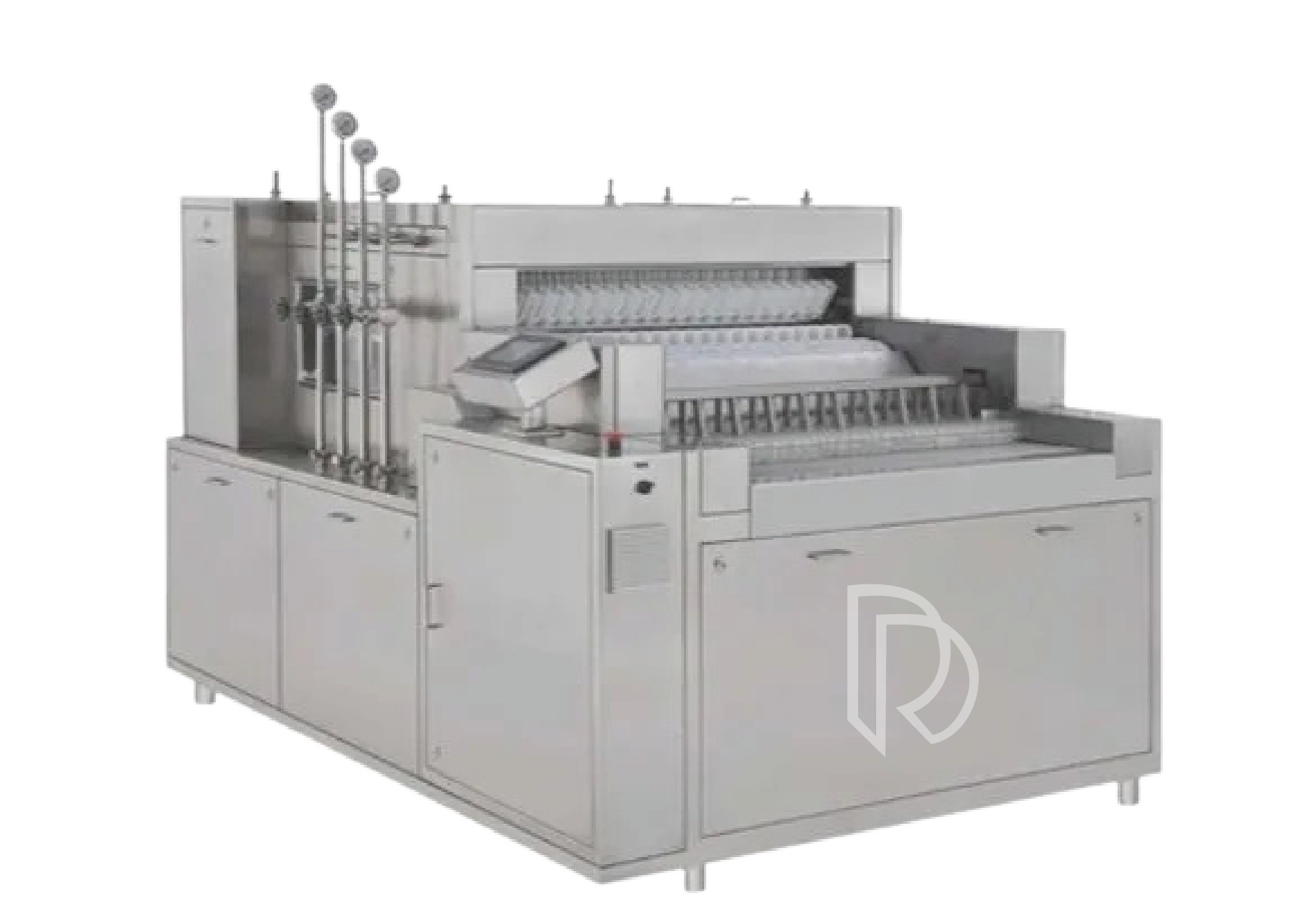

- GMP Model

- One Set of Change Parts suitable for 5ml to 30ml vial having 20 mm neck dia.

- 3 Nos. SS-316 Tanks (50 Ltr. Each.)

- 3 Nos. SS-316 Centrifugal Pumps

- 1 No. each for Re-circulation Water, DM Water and WFI Water.

- 4 Nos. SS-316 Filter Housing with its cartridges.

- 1 No For Re-cycle Water : 10” Size, 10 Micron

- 1 No. For Fresh DM Water : 10” Size, 5 Micron

- 1 No. For Fresh WFI Water : 10” Size, 5 Micron

- 1 No. For Compressed Air : 5” Size, 0.2 Micron

- 4 Nos. Pressure Gauges – Glycerin Filled.

- Inbuilt Infeed SS-304 Wiremesh Conveyor

- A. C. Frequency Drive for Speed Control.

- Individual Solenoid Valve for Wash Media Operation.

- All pipe fittings (Water Contacts) are of made from SS-316 material.

- Gear Box and Motor for Main Machine and Infeed Conveyor.

- Emergency Switch on Control Panel & Outfeed.

- Outfeed can connect directly to Sterilizing Tunnel or can collect it in the trays.

- Output : Upto 120 VPM (Depends upon Vial Size)

- Push Button Based operating Controls.

Safety & Interlocks

- Main Motor Overload – Machine Stop

- Infeed Lifter Jam – Machine Stop

- Emergency Stop (Both End) – Machine Stop

- Outfeed Lifter Jam – Machine Stop

- Outfeed Pusher Jam – Machine Stop

- Outfeed Prism Jam – Machine Stop

- Re-Circulation Water Level Low – Light Indicate/Machine Stop

- DM Water Level Low – Light Indicate/Machine Stop

- WFI Water Level Low – Light Indicate/Machine Stop

Change Parts (If required – later on) – Means Machinecapable to run upto Max. 30ml Vial only

-

Changeover of Vial Sizes (2ml Vials – 13mm Neck Dia)

-

Complete Channel (40 Nos.) with its vial holder cup (400 Nos.) fitted.

INTERNAL WASH :

- 1st WASH COMPRESSED AIR

- 2nd WASH RE-CIRCULATED WATER – DRAIN

- 3rd WASH RE-CIRCULATED WATER – DRAIN

- 4th WASH COMPRESSED AIR

- 5th WASH FRESH DM WATER – COLLECT IN RECIRCULATION TANK

- 6th WASH COMPRESSED AIR

- 7th WASH FRESH DM WATER – COLLECT IN RECIRCULATION TANK

- 8th WASH COMPRESSED AIR

- 9th WASH FRESH W F I WATER – COLLECT IN RECIRCULATION TANK

- 10th WASH COMPRESSED AIR

EXTERNAL WASH :

2nd WASH RE-CIRCULATEDWATER

7th WASH FRESH DM WATER

- Washing Sequence having flexibility.

- All Wash Media is passed through its individual and separate spray pipes & Nozzles

- Number of Cups / Row : 10 Nos. Cups / Row

- Number of Channel : 40 Nos.

- Total Number of Cups : 400 Cups / Machine

- 10 Inner Washing Spray Pipes & 2 Outer Washing Spray Pipes

- 100 Inner Washing Nozzles & 20 Outer washing Nozzles

Optional Accessories :

- PLC with HMI Touch Screen (Delta Make)Safety & Interlocks

- Three Level Access (Operator, Supervisor & Maintenance Mode)

- All Interlocks with Buzzer / Display in HMI Touch Screen.

- Main Motor Overload.

- Infeed Lifter Jam

- Emergency Stop (Both End)

- Outfeed Lifter Jam

- Outfeed Pusher Jam

- Outfeed Prism Jam

- Jog / Inching through HMI

- Re-Circulation Water Level Low

- DM Water Level Low

- FI Water Level Low

Pressure Transmitter for All Wash Media [If PLC Based Machine] :

- Re-Circulation Water Pressure Low – machine stop

- o DM Water Pressure Low – machine stop

- o WFI Water Pressure Low – machine stop

- o Compressed Air Pressure Low – machine stop

Material Of Construction :

- Machine frame structure SS-304

- Door Set SS-304

- Control Panel SS-304

- All Water Contact Parts SS-316 HDPE, Food Grade Material

- Infeed Inbuilt Conveyor SS-304 Wiremesh

- Pocket Drive Chain SS-304

- Vial Holder Pocket / Cups HDPE – Food Grade Material

- Flexible Pipe Silicon – Food Grade Material

- Pressure Gauge SS. Glycerin Filled

- All Shafts SS-304

- Pumps Contact Parts in SS-316

- Filter Housing SS-316

- Tanks 3 Nos. SS-316 – 50 Ltrs. Each.

- 14. All Pipe Fittings SS. Sanitary Type

Make Of Brought Out Items :

- All contactor and relay Telemechanic / Schneider

- Limit Switch Teknic / BCH / Schneider

- Pumps CNP

- Pressure Gauge Shreeji

- Main Gear Box & Motor Bonvario

- Conveyor Gear Box & Motor Bonvario

- Solenoid Valve Rotex

- A.C. Drive Delta

- PLC & HMI Delta (Optional)

Utility (To Be Provided at Site) :

- 1 Power Total : 5 HP, 3 Phase, 50 Hz.(1 HP for Each Pump, 1 For Machine, 0.25 HP for Conveyor)

- 2 Compressed Air 35 to 45 CFM at 4 Kg/Cm2 to be provided at Site from Utility.